Special features of goods

6 steps of our perfect quality testto build high reliability

-

· Quiet Operation

-

The unique design of air end which adopts double casing minimizes the noise during air compressing process. The Silencer and Sirocco fan were simulated by air flow analysis before manufacturing, which reduce air friction noise remarkably. Casing inside is covered with high density sound absorbing material for the reduction of sound level. Also a unique quick venting valve which is designed for eliminating unloading noise is installed..

-

· Energy saving

-

BUMACOMPRESSOR.com has developed big size screw rotor of air end by high precision machining process, and as a result we've achieved the best clearance of the rotor which is the highest level of air flowrate in the world. There is no inter mediate speed control mechanism between motor and rotor for increasing driving power efficiency. And there also adopted high efficient centrifugal fan and energy saving intake valve system,

-

· Human-oriented Arrangement

-

BUMACOMPRESSOR.com’s air compressor is designed for convenient maintenance. All the parts are arranged and assembled for save maintenance time, those are mobile hinged casing doors, bolted separator tank cover with O-ring seal, and etc. Furthermore, it is simple to clean inside of air compressor.

-

-

· BUMACOMPRESSOR.com Is Your Trustworthy Brand

-

-

· High Efficiency Motor

- Specially ordered high efficiency electric motors have been adopted for BUMACOMPRESSOR Air Compressor. Especially for increase efficiency, we've adopted frequency conversion motor which is controlled by loading/unloading. By reducing energy conversion loss and restrict temperature rising, the motors can be sustained long lifetime without break down and burn out..

-

-

· High efficiency, Energy saving Air End

- The latest knife edge technology with exclusive design is adopted for BUMACOMPRESSOR’s new Screw Rotors, and through the precision machining and grinding process, the rotor sealing is improved and optimized for high efficiency. The material of rotor is high strengthened special steel which characteristics are durability and very least deformation. The unique design of bearing support and adopting roller bearing can be supported thrust load of rotor, hence extended the running time..

-

-

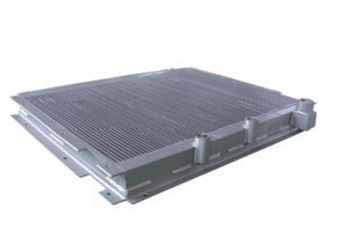

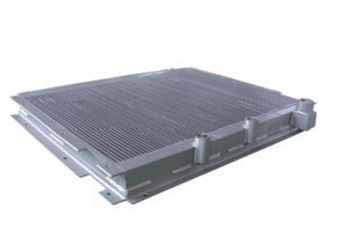

· Cooling System

- Air flow design for cooling system can be sustain canopy inside temperature as a good condition, and make compressed air exhaust temperature as stable. Through the high temperature test in the laboratory assuming severe condition, it verified for normal operating condition.

- The detachable cooling fan and motor ensure stable operation even the circumference temperature reaches 50'C. The compressor models equipped 110kW motor or more, it equipped combined cooling system for air cooling and oil cooling so that the weight can be less, and maintenance time and cost can be reduced.

- By adopting plate fin cooler which equipped aluminum plate fin can be reduced flow resistance and be increased cooling efficiency..

-

-

· Centrifugal Fan Blower for cooling

- Revolution speed of 6p electric motor is relatively low compare to 4p motor, hence the noise is reduced and the cooling efficiency is increased. Further more it's composition is so simple as to make maintenance free.

-

-

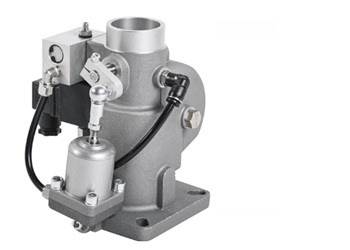

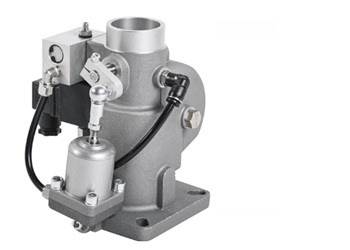

· Energy Saving Intake Valve System

- The advantage of this valve is high efficiency and can be controlled full volume. This valve is function integrated for unloading, intake, and exhaust with volume adjustment, and body also is integrated with electromagnetic valve, exhaust valve, and valve body.